WHAT WE DO

Aggregates Crusher Parts

A Quality Product That Can Increase Your Crushing Efficiency

Welcome to the world of aggregates crusher parts, where efficiency and performance are key to success. Whether you are a mining operation, construction company, or recycling facility, ensuring the proper functioning of your crushers is vital for maximizing productivity and reducing downtime. In this article, we will delve deep into the realm of crusher parts, offering valuable insights, tips, and best practices to help you achieve the best possible results.

Aggregates Crusher Parts: Understanding the Essentials

The Role of Crusher Parts in Crushing Operations

Crusher parts play a crucial role in the crushing process. They are the components responsible for breaking down large rocks and materials into smaller, manageable sizes, making them suitable for further processing.

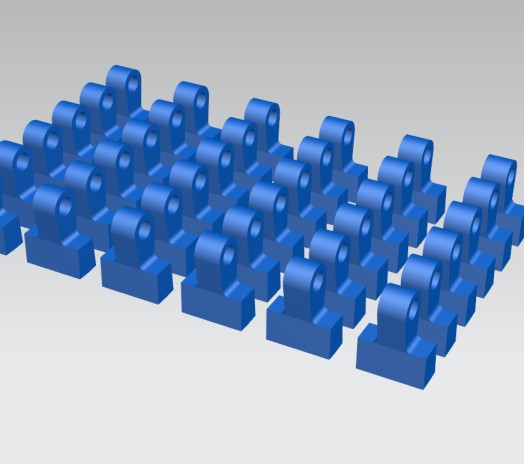

Types of Aggregates Crusher Parts

Explore the various types of crusher parts used in different crushing equipment, such as jaw crushers, cone crushers, impact crushers, and gyratory crushers. Learn about the functions of each part and how they contribute to the overall crushing process.

Key Components of Crusher Parts

Delve into the intricacies of crusher parts, including jaw plates, concaves, mantles, blow bars, and more. Understand the significance of each component and how they interact to ensure efficient crushing operations.

Choosing the Right Crusher Parts for Your Application

Selecting the appropriate crusher parts for your specific application is crucial for optimizing performance. Learn the factors to consider, such as material composition, hardness, and compatibility with your equipment.

Importance of Regular Maintenance

Discover the importance of regular maintenance for your crusher parts. Proper upkeep can extend the lifespan of your components, minimize downtime, and enhance overall operational efficiency.

How to Identify Wear Patterns

Learn how to identify wear patterns on crusher parts, such as abrasion, erosion, and impact wear. Understanding wear patterns can help diagnose potential issues and optimize your crusher's performance.

Enhancing Crusher Efficiency

Discover techniques to maximize crusher throughput and achieve higher production rates. Efficient throughput is essential for meeting production demands and minimizing operating costs.

Maximizing Crusher Throughput

Discover the importance of regular maintenance for your crusher parts. Proper upkeep can extend the lifespan of your components, minimize downtime, and enhance overall operational efficiency.

Reducing Downtime with Quick Parts Replacement

Learn about the benefits of quick parts replacement and how it can significantly reduce downtime during maintenance or component replacements.

Recycling and Sustainability: The Role of Crusher Parts

Explore the role of crusher parts in recycling applications and how they contribute to sustainability efforts in the construction and mining industries.

Innovations in Crusher Part Design

Stay updated on the latest innovations in crusher part design, such as advanced materials and wear-resistant coatings, to optimize performance and extend component life.

Safety Considerations for Crusher Parts

Safety is paramount in any crushing operation. Understand the safety considerations and best practices when working with crusher parts to prevent accidents and injuries.

Troubleshooting Common Crusher Part Issues

Learn how to troubleshoot common crusher part issues, such as excessive wear, misalignment, and component failure, to ensure smooth and uninterrupted crushing operations.

The Role of Lubrication in Crusher Part Performance

Explore the critical role of lubrication in maintaining optimal performance and extending the life of crusher parts. Understand the best lubrication practices for different components.

The Role of Lubrication in Crusher Part Performance

Discover effective strategies to extend the lifespan of your crusher parts, reducing the frequency of replacements and lowering maintenance costs.

The Future of Crusher Part Technology

Stay ahead of the curve by exploring emerging trends and technologies in crusher part design and manufacturing, and how they can shape the future of the industry.

FAQs: Your Top Questions Answered

To choose the right crusher parts, consider factors like material type, feed size, desired output, and compatibility with your equipment. Consult with experts and manufacturers for tailored solutions.

The replacement frequency depends on various factors like material properties, operating conditions, and maintenance practices. Regular inspection and monitoring can help determine the optimal replacement interval.

It is not recommended to use non-genuine parts, as they may not meet quality standards and can compromise performance and safety.

Regular maintenance, proper lubrication, and adherence to best practices can significantly extend the lifespan of crusher parts.

Crusher parts are crucial for breaking down and processing recycled materials

HOW WE WORK

Top Working Process

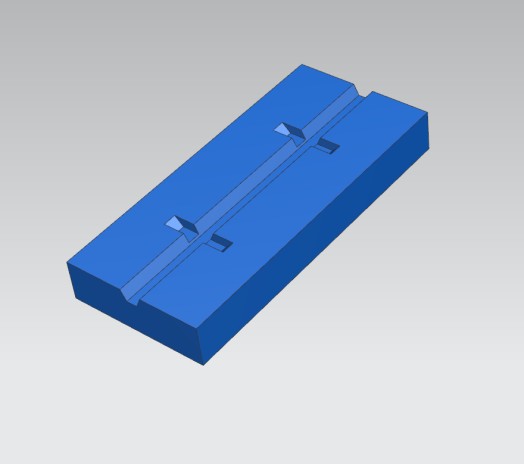

Our working process involves meticulous analysis, precision engineering, and rigorous testing, guaranteeing top-notch crusher spare parts for superior performance.

BRAINSTORM

DEVELOPMENT

DELIVERY

Related Services

Custom Solutions to Suit Your Need

Explore our related services, including equipment maintenance, technical support, and customized solutions to meet your specific requirements and challenges.