WHAT WE DO

The Crucial Role of Recycling in Stone Crushing Parts for Sustainable Construction

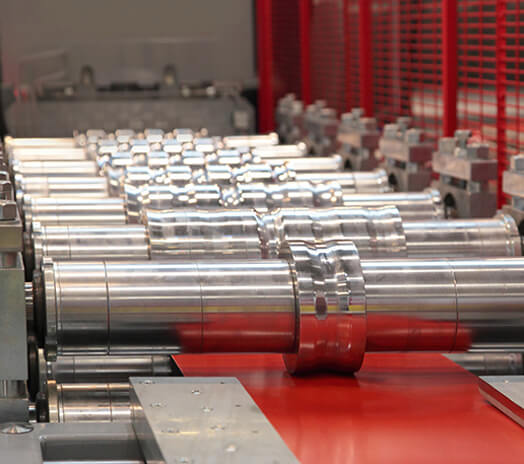

A Quality Product That Can Increase Your Crushing Efficiency

Recycling in stone crushing has emerged as a key player in sustainable construction practices. By repurposing stone crushing parts, such as concrete and asphalt, recycling not only minimizes waste but also contributes to a greener construction industry. This article delves into the importance of recycling in stone crushing parts and its positive impact on building a more environmentally conscious future.

Why Recycling Matters:

Recycling in stone crushing is a cornerstone of sustainability. The process involves transforming discarded concrete and asphalt materials into reusable aggregates, significantly reducing the demand for virgin resources. This not only conserves natural materials but also mitigates the environmental strain caused by extraction and transportation.

Benefits of Recycling Stone Crushing Parts:

Environmental Conservation:

Recycling reduces the burden on landfills and decreases the energy required to produce new aggregates. It cuts down on carbon emissions and conserves valuable natural resources, promoting a healthier planet.

Cost Efficiency:

Using recycled stone crushing parts can be cost-effective for construction projects. It eliminates the costs associated with mining, processing, and transporting virgin materials, thereby lowering overall project expenses.

Versatility in Applications:

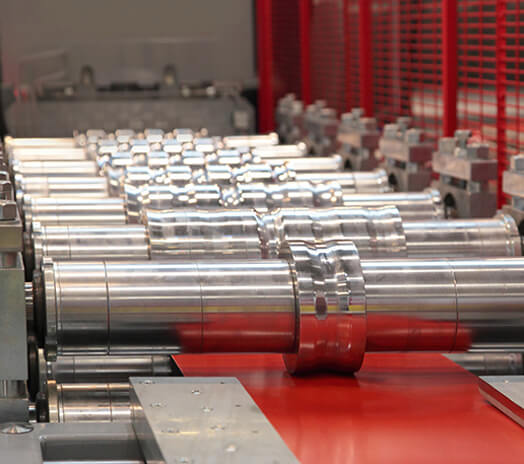

Recycled aggregates from stone crushing parts can be used in various construction applications, including concrete production, road bases, and drainage systems. Their versatility makes them a suitable alternative to traditional aggregates.

Regulatory Compliance:

Many regions encourage or require the use of recycled materials in construction to meet environmental regulations and reduce the impact of waste disposal. By incorporating recycled stone crushing parts, construction companies can ensure compliance with these regulations.

Enhanced Reputation:

Construction companies that prioritize recycling and sustainable practices tend to have a positive reputation among environmentally conscious clients. Using recycled stone crushing parts can improve a company's image and attract more eco-friendly projects.

Conclusion:

The role of recycling in stone crushing parts cannot be understated. It aligns with the global push for sustainability and responsible resource management. By repurposing stone crushing materials, construction projects can contribute to a cleaner environment, reduce costs, and showcase their commitment to a greener future. As the construction industry continues to evolve, embracing recycling in stone crushing parts is a crucial step toward building a more sustainable world.

FAQs: Your Top Questions Answered

Recycling in stone crushing parts involves repurposing materials like concrete and asphalt, contributing to sustainable construction by reducing waste and conserving resources.

Recycling minimizes the need for new materials, reducing resource extraction and waste accumulation. This practice supports a cleaner environment and reduced carbon footprint.

Materials like discarded concrete and asphalt can be crushed and transformed into reusable aggregates for various construction applications.

Recycling involves crushing demolished concrete and asphalt, followed by screening and sorting to create aggregates suitable for construction use.

Recycling lowers costs by minimizing the reliance on new aggregates. Additionally, it reduces the negative impact of raw material extraction and transportation.