WHAT WE DO

Mining Spare Parts

A Quality Product That Can Increase Your Crushing Efficiency

In the dynamic world of mining, reliable equipment is the backbone of successful operations. Mining machinery endures rigorous conditions and heavy workloads, making regular maintenance and occasional replacement of spare parts a critical aspect of sustaining productivity. This comprehensive guide delves into the realm of mining spare parts, shedding light on their significance, types, and best practices for selection and maintenance.

Mining Crusher Parts: Understanding the Essentials

The Crucial Role of Mining Spare Parts

Mining spare parts play a pivotal role in maintaining the seamless flow of operations. From excavators to drills, these components are the lifeblood of heavy machinery, ensuring smooth functioning, reducing downtime, and optimizing overall efficiency.

Types of Mining Spare Parts

Mining equipment comprises a multitude of parts, each contributing to specific functionalities. Some essential types of mining spare parts include:

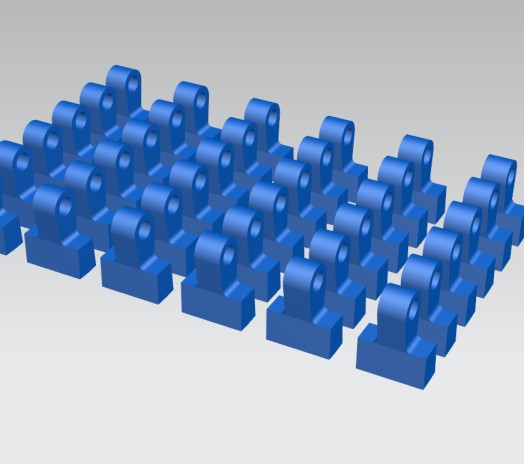

Mechanical Components:

Bearings, gears, chains, and belts form the mechanical backbone, requiring periodic maintenance to prevent breakdowns.

Electrical Components:

Wiring, sensors, and switches are integral for controlling and monitoring equipment, enhancing safety and performance.

Hydraulic Components:

Hydraulic cylinders, hoses, valves, and pumps power heavy machinery, demanding regular inspection and care.

Filters and Lubricants:

Filters and lubricants are essential to maintain machinery efficiency and extend longevity.

Safety Equipment:

Brakes, lights, alarms, and emergency systems contribute to on-site safety and require vigilant upkeep.

Control System Components:

These parts manage equipment operations and demand specialized attention to ensure precision and reliability.

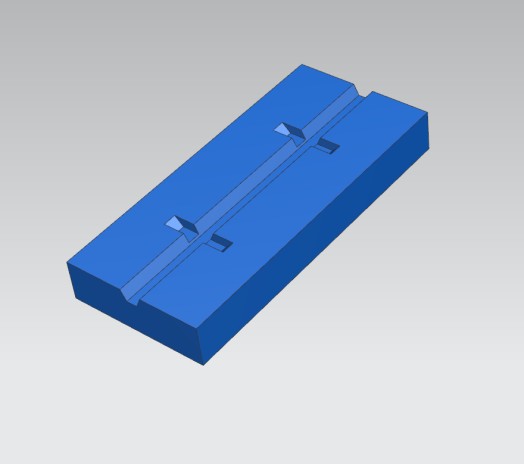

Structural Components:

Frames, chassis, and structural supports are critical for equipment stability, necessitating thorough inspection and repair.

Choosing the Right Mining Spare Parts

Selecting appropriate spare parts is a strategic process that involves:

Understanding Equipment Needs

Recognizing which spare parts are critical for specific machinery to prioritize replacements effectively.

Quality Assurance:

Opting for genuine OEM parts or high-quality alternatives to ensure compatibility and reliability.

Vendor Relationships

Cultivating partnerships with reputable suppliers ensures timely access to genuine spare parts when needed.

Maintenance and Replacement Practices

Regular equipment assessments aid in identifying parts that require replacement before failures occur Adhering to manufacturer-recommended maintenance schedules prevents untimely breakdowns.

Ensuring Longevity and Efficiency

Implementing effective lubrication practices enhances the lifespan of mechanical components Maintaining optimal operating temperatures and protecting equipment from harsh environments are vital.

FAQs: Your Top Questions Answered

Mining spare parts are crucial for maintaining the functionality and efficiency of heavy machinery used in mining operations. These parts help prevent breakdowns, reduce downtime, and ensure uninterrupted production.

Choosing the right spare parts involves understanding your equipment’s needs, prioritizing critical components, opting for quality OEM or reputable alternatives, building relationships with reliable suppliers, and implementing efficient inventory management systems.

Regular maintenance and timely replacement of spare parts are essential to prevent equipment breakdowns, extend machinery lifespan, and maintain operational efficiency. Neglecting maintenance can lead to costly downtime and repairs.

Scheduled inspections should be conducted regularly, with frequency depending on equipment usage and manufacturer recommendations. Preventive maintenance schedules help identify parts requiring replacement before they fail.

Data-driven insights help in identifying usage patterns, predicting maintenance needs, and optimizing spare parts replacement schedules. This approach minimizes downtime and improves overall efficiency.

[porto_animatio

HOW WE WORK

[porto_animatio